CARPENTER AND TILDESLEY, SUMMERFORD WORKS, WILLENHALL

Curator's note: The Tildesleys have long been

associated with Willenhall and members of the family have, from time to

time, been connected with a variety of businesses. Much time and

effort has been spent in trying to sort out the history of these

inter-connected companies. What follows is Jim Evans' account of this

one firm, which started out as James Carpenter and became Carpenter and

Tildesley, under which name they continued until about 1919 when trading

under that name seems to have come to an end.

James Carpenter, although not a native of Willenhall, eventually

became one of its worthies. He was born in 1775 and come to the town in his early

life; in 1795 he started to make ironmongery. In 1815 he invented a new type of

curry comb for horses and patented it (no. 3956). In 1830, jointly with John Young

of Wolverhampton, he took out patent no, 5880, an improved design of latch bolt and

lock. The two agreed to divide the patent into rim lock use and mortice lock use,

James Carpenter going on to construct rim locks while John Young had the right to make

mortice locks. Carpenter named his rim lock "Number 60". It became known

as "Carpenters lift up lock". It was his invention to make the latch

perpendicular instead of horizontal, which renewed the vitality of the town's staple

industry. As his business grew he erected a large factory in New Road, known as

Sommerford Works. James Carpenter died in 1844, aged 68, and a memorial was erected

outside the Wesleyan Methodist Church, Union Street, Willenhall where he was a member.

John Carpenter and James Tildesley, a local locksmith who had married

James’s daughter Harriet, inherited the company. The name of the company was

changed from Carpenter and Co. to Carpenter and Tildesley, in 1851.

|

Trevor Dowson has found this

advert in the Birmingham Directory for 1845. It shows that the

name Carpenter & Tildesley was adopted earlier than Jim Evans

thought. |

They made an

ornamental lock that was exhibited at the Great Exhibition. In 1852 James Tildesley

disposed of his various business interests and dissolved his partnership with John

Carpenter (died 1857), and became the sole owner of Carpenter and Tildesley. He

developed a large business exporting his locks to Australia. In 1870 James Tildesley

patented number 2440, a new type of rim lock. The main feature was that it was

double handed, which means it could be used on a right or left hand door. The lock

was called the J25. James died in 1876 and the control of Carpenter and Tildesley passed

to his sons, James C. and Clement. They took out a patent, Number 14917, a new process for

plating door handles.

By 1888 they were experiencing problems with other manufacturers copying

their locks. Their entry in Kelly’s Directory contained the following

statement: "Sole manufacturers of Carpenter No. 60 lock, and all kinds of door locks.

To avoid spurious imitations fraudulently marked and numbered, buyers should in all cases

specify 'Carpenter and Tildesley' make."

James was invalided in 1904 and died three years later in 1907 age 67.

In 1915 Clement signed a lease with G. R. Smithson and Co., drop forgers,

for the lease of Summerford House, originally the home of James Carpenter and then the

Tildesleys. Clement died in 1919 age 75. By this time many Willenhall

companies were making the No 60 lock and it appears that Carpenter and Tildesley ceased

manufacture. And any reference to Smithsons was at their Cannock Road, Wolverhampton

address. See article by David Hunt.

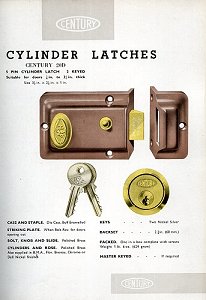

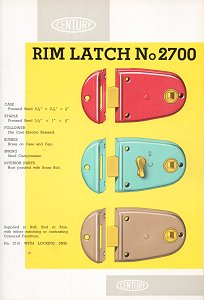

CENTURY LOCKS LTD, CENTURY WORKS, MOAT STREET,

WILLENHALL (1814-1990)

|

When it is realised that this company was founded in

the year Napoleon abdicated, and that Wellington was created a Duke, the mind begins to

appreciate its great age.

In 1814 - the year before the Battle of Waterloo - Humphrey and John Fox

joined forces to set up in business as locksmiths at Number 11 John Street, Willenhall.

(Kelly’s 1888)

The original premises comprised two houses with a small workshop at the

rear. One of the houses served as a store room and office. |

It was adequate for the small amount of administrative

and office work necessary in those days, as hard, long hours at the bench were the recipe

for success then. Working hours were from 6am till 8pm and lighting was by paraffin lamp

and candles. When orders on hand demanded it, often it became necessary to work on till

11pm, with only a short break for quick refreshment at the "Ring O’ Bells"

opposite. However, the business prospered. A two-storey workshop was erected and the

horse-drawn vehicles of the day were regularly delivering products to the whole of the

Birmingham area.

The business was already "old-established" - in fact 40 years

old - when the Crimean War occurred in 1854. This fact makes one realise how many

vicissitudes of war and peace it has survived to become the source of livelihood of so

many Willenhall people. The year 1880 saw the beginning of a new era when Humphrey Fox II

joined the business. As the last decade of the nineteenth century approached the business

was growing to such an extent that more commodious premises had become an urgent need.

Thus, in the year 1890, the business was moved from the old John Street premises to a site

that was formally an old moat, to form Moat Street Works.

| With the Boer War come and long gone, 1906 witnessed the arrival of a

founder’s grandson into the business - Humphrey Fox III. Eight years later, the 100th

birthday of the firm coincided with the outbreak of World War I in 1914. Young Humphrey

Fox joined up the same year but in 1917 he received severe leg wounds and was invalided

out of the army. His father died in that year. |

|

In 1920, two years after the war ended, Charles Morgan,

who was an uncle of Humphrey Fox III, entered the business and became

the first representative of the Morgan family to be actively concerned

with the running and the development of the Company.

| Only a year later, in 1921, Charles Morganís

son Norman started work with the company at the age of

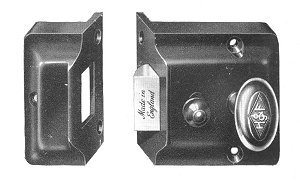

fifteen. By this time they had started to

manufacture cylinder pin tumbler locks, and were founder

members of the British Cylinder Night Latch Association when

it was set up in 1928. |

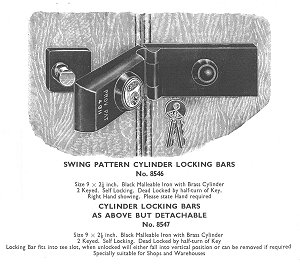

Trade catalogue entry

for a swing pattern locking bar. By courtesy if Trevor

Dowson. |

|

|

Norman Morgan recalled the ancient machinery and archaic methods of those

days - how lock cases were black-japanned hand-painted and dried in coal-fired stoves

taking ĺ hour to dry. By 1964, with more modern plant, components were sprayed

and conveyed to an infra-red drying oven taking only 10 minutes continuous oven time. It's

a wonder how the company ever managed in those days.

An expansion programme initiated in 1936 saw the erection of modern factory workshops.

The policy of modernisation was continued so that employees were housed in open, light

airy workshops. |

In 1929 Reg Morgan, Charles younger son, joined the company and

inaugurated a new side to the business when he formed R H Morgan to manufacture tools and

produce pressings for the motor trade and to do die-sinking and make drop forging. Under

Reg’s control development went ahead. In 1940 a site of 9 Ĺ acres was purchased at

Ashmore Lake.

|

| This purchase was originally made with the intention of moving the parent

company, as Moat Street was getting somewhat congested. In 1955 the

neighbouring company of Samuel Baker & Co., who made galvanised and brass padlocks,

was purchased to provide additional space and the two factories were joined together to

form a larger Century Works. So the lock making company was never moved off the Moat

Street site.

Reg Morgan passed away in 1961 and in the following year Humphrey Fox III died, aged

81; and then, on the 1st February 1963, Charles Morgan died in his 83rd year.

Thus in a short span of three years the company had lost three directors. |

|

The board was reformed with the addition of Barrie

Morgan, the son of Reg, together with a number of non-family members. Between 1968 and

1978 the two companies split and the lockmakers changed their name from Humphrey and J Fox

to Century Locks.

Although only a relatively small lock and latch manufacturer, they had

built a high reputation for quality. In October 1987 the Chairman and Managing Director,

Norman Morgan, decided to retire at the age of 82 and sell the business. It was sold to Mr

Barrie Bernstein (MD of kitchen makers Home Charm) and Gordon Fernley (former MD of

Polycell). At the time they pledged to expand the company and to increase its then 120

work force. Keith Whitehouse, the son in law of Mr Morgan, remained as a director.

Less that three years later, in August 1990, the company was purchased by

Yale and by November 1990 the Moat Street works had closed and production moved to Yale

works in Wood Street.

(Ref.- A century and a half of progress 1814 -1964 published by the

company)

C.W.CHENEY AND SON LTD, FACTORY ROAD, HOCKLEY,

BIRMINGHAM

A manufacturer of locks and hinges for travel goods, founded about

1920. |

|

In 1990s the company was purchased by a German Company, Franzen, who then

sold out to a venture capital company in 2000. On the 1st June 2000 they

acquired Liston Products (Bridgetown) Ltd (q.v.) and all production was moved to

Birmingham. |

In January 2001 (Sunday Mercury) Official

Receivers were put into close the company down. There had been some irregularity over the

administration of the pension fund and possibly £3,000,000 had gone missing. The

firm was acquired by F.H.Tomkins Buckle Company Ltd. of Brockhurst Crescent, Walsall on

the 31st January 2001. Manufacture continued at Factory Road for a short

time but then transferred Walsall. The Receivers settled all the liabilities

relating to previous trading by Cheney prior to the changeover. (FHT letter 14/2/2001) |

GEORGE CHEADLE LTD, 142 HORSELEY FIELDS

ROAD, WOLVERHAMPTON

Existing in 1936 and 1974 but nothing else known.

CHUBB LOCKS LTD, WEDNESFIELD ROAD, WOLVERHAMPTON |

Read the history

of Chubbs |

|

|

|

|

| Return to Locks and Safes |

|

Return to the list of makers |

|