|

|

This photo of Gibbons staff

was probably taken at about the turn of the century. There

are 39 people in it. They are probably the office staff. (photo

by courtesy of Frank Spittle) |

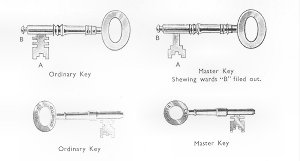

On the 29th November 1899 Mr. F J J Gibbons was granted a

patent for the "Mastership" two-keyhole lock. This made master keying of

mortice locks more secure, as the master key was inserted into a separate keyhole from the

ordinary key and was of a different form. This meant that a master key

could not be made by the simple process of filing off parts of one of

the ordinary keys.

A Gibbons' catalogue of 1952 explains the Mastership system:

"In making locks to differ under the old system, the levers (A) of

the locks must all be made the same so that the master key may go over

them and the only variance that is made on the locks is on the wards

(B). It is thus simple for the ward to be filed out and an

ordinary key made into a master key. This has already been done at

a large hotel in London.

|

With the two keyhole system all the locks are

varied on the levers, so that none key does not indicate in the

slightest manner what another key may be on the building.

It ios therefore impossible to alter an ordinary key into a

master; they vary in size the master key being larger than

the master." |

You could also have a three tier system so that the ordinary

keys would, for example, only open one hotel room door, the master key

would, open all the doors on one floor of the hotel but not those on any

other floor, but the Grand Master Key could open any door on any floor.

The original "Mastership" lock was replaced in 1960 by a new patent system for a wardless lock

on a single keyhole system. The "New Mastership" system achieved the same

degree of security without the complication of the larger size of the two key lock.

Gibbons had over 200 patents and registered designs. In addition, by

the mid 1920s, they had designed and made a "Thief Proof Rim Night Latch" to

combat the competition from the "Yale Cylinder Pin Tumbler Lock".

|