Whilst keys are mainly inert things without any mechanical operation they can be fascinating items to collect. There exists a great variation in age, type, and style, with many having intricate and decorative designs. The earliest keys are those which operated the Egyptian pin tumbler locks from about 4,000 years ago. Information about these is provided in several books dealing with the history of locks and keys, so we will commence by looking at the type of keys made from medieval times.

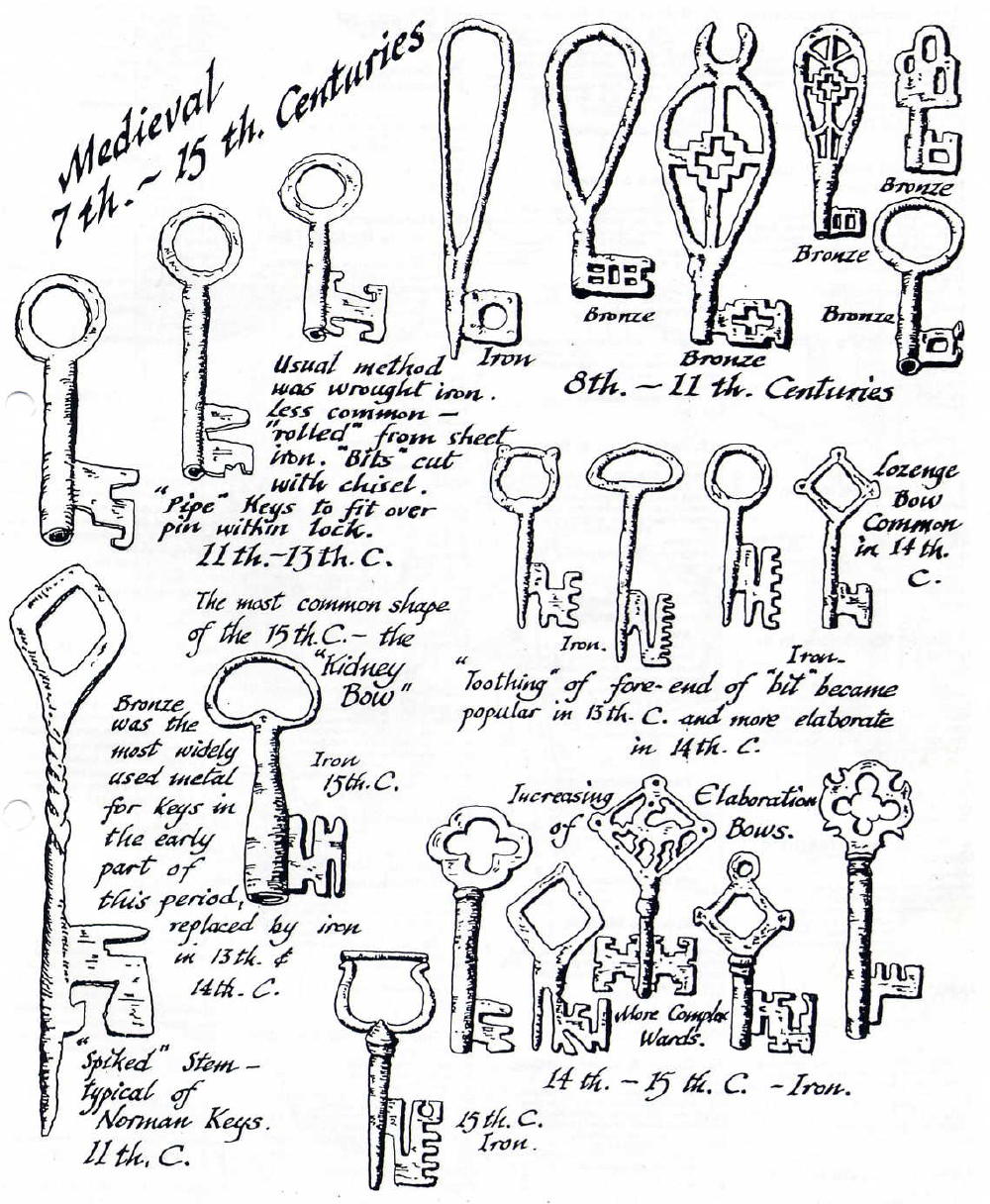

Here below are illustrated the types of keys made from that time up to the 15th century:

(My thanks to Richard Phillips for allowing me to copy this from his Locks & Keys Newsletter of November 2001, No.16- it provides a handy illustrative reference to the key styles over that period).

From c.1750 the elaborate and decorative key designs were replaced by those of a simple and plainer nature. The keys then had nicely formed wire bows, with the bits exactly cut; and their shafts had typical Georgian style turning. Before 1806 all keys were made in the forge, a slow and laborious procedure of hammering into shape, using a superior quality of iron made from swarf, or iron filings rolled into “swarf balls”.

Iron was chiefly used in early key manufacture either in the wrought form, or by malleable casting introduced in the mid-19th century (Though, early English finely made keys elaborately designed with fancy bows were case hardened and thus called a steel key). By the 1870s steel was more widely used, possibly through the Bessemer Converter invention of 1856 that converted cast iron directly into steel.

Prejudice against change stopped the general use of stamped keys, but from 1811 key forging was gradually replaced. Stamped keys were made in the traditional Blacksmith's forge, using fire and bellows. After heating the red hot end of a metal iron rod would be placed into a half mould of the key shape. Above it was a heavy weight with the other half of the mould on its underside, and it was raised by a pull cord between vertical guides. When released both halves of the mould came sharply together, stamping the red hot iron to form a rough key shape. This apparatus also allowed the rough key to be trimmed by a single blow from above to remove the surrounding surplus metal, or punch out metal to form the bow.

Children were used to blow the forge bellows, whilst young men placed the heated rod in the mould and adult workers attended to the stamping. Pipe keys had to be pierced with foot treadle drills. The filing process then finished the key, excess metal was removed, clefts for the wards were cut into the bit using a file and cold chisel, and the key made bright with the file.

Casting of keys was not generally undertaken until Richard Tildesley of Wolverhampton was able to perfect the manufacture of malleable iron castings around the 1840s. First to produce locks and keys by this method is attributed to John Harper Jr. & Co. A Bramah key taken from the sand by this method was shown (c.1856) to be “without a mark or blemish of any kind, and the cuts in the barrel are quite perfect”. So this eliminated the protracted process of stamping, pressing and filing.

Inevitably, replacement of the hand operated stamping process began about 1850 when Harper and Tildesley of Willenhall adapted Naysmith's steam hammer invention to stamp locks and keys, that produced a better product at a cheaper rate. This period might well be seen as a beginning of the lock and key making trade moving away from being a branch of the Blacksmith's business towards that of becoming part of the Engineering industry.

Several books are available to provide further reading on this subject and a modestly priced work is Eric Monk's “Keys, Their History and Collection” first published by Shire Publications Limited in 1974. Shown below are a few examples of interesting keys available to the collector:

The key above shown is a typical finely produced item of English manufacture around 1800. It has a Georgian wire bow, nice shaft turning, intricately cut wards on the key bit, and a dust stopper - all of which indicates a quality made key, probably for use on an early cast iron safe.

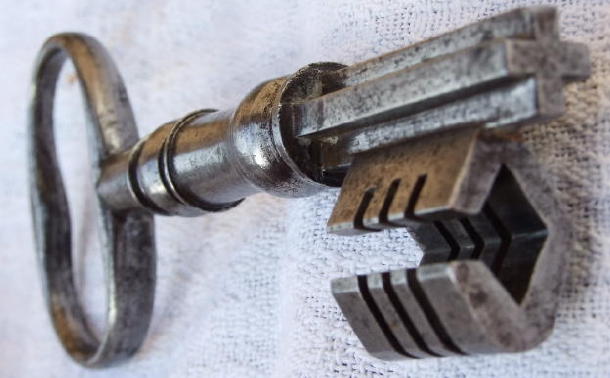

A similarly made key is shown below; however the added nicety of this is the steps cut into the bit end, which indicates that they are provided to lift the tumblers (possibly three in number) of a Barron lock, in addition to the warding system. It is likely also to have been used on a cast iron safe c.1810.

This key below is a very rare, I'm told it was only issued to Service Engineers. It was used to open the lock on the steel door, which is on the back of huge vault doors. The prongs are to unscrew the various bolts (having a round flat head and two holes in them) around the edge of the same door.

Below is the reverse side: 3.4” long and stamped “Chamber Lock”, used in a Bank Vault – c.1900.

A strange looking operational end of a probably English key of the 18th Century. 5.5” (14cm) long.

18/19th century key. Chased and decorated and in excellent condition. A beautifully engraved pipe key, probably used on an early safe – 5” (12.7cm) long.

The reverse side of this fine key is shown below:

William the Fourth reigned from 26th June 1830 to 20th June 1837. Keys were often stamped with the Royal Crown and initials of the Monarch, “W.R.” in this case. It looks to have been used on a four lever lock. I has some slight wear with a small crack having developed along the stem:

S. Whitfield & Son, Oxford Street, Birmingham No. 8046, shows business end of rare 12 Slider key, c.1860s

Charles Smith & Co. Ltd. of Birmingham were specialists in the making of Jail Cell locks in the mid/late Victorian period and their keys tended to have decorative bow designs, like this below It is just 3.4” (8.6cm) long:

A most unusual key is that for the O'Dell night latch invented around 1792 (although this was the first British version as the French were making this type of latch in the 17th century). As shown by the brass front of the latch it is has a spade shaped key bit. This enters the inverted “T” shaped slots and passes into the back where it is lifted through the wards shown in the R.H. photo to lift a latch.

A Victorian era American key by Lewis Lillie of the Lillie Safe Co in Troy, New York, with its changeable bits.

A major improvement made to American bank locks was that invented by Robert Newell of New York City; Patent No 944 of September 25th, 1838, being made by Day & Newell Co. This photograph shows the key with its 8 changeable bits. The lock, commonly known as the American Parautoptic lock, was almost unknown in England until the Great Exhibition of 1851. In this year Newell acquired a British patent incorporating his previous improvements (Patent No 13,595 of April 15th, 1851). Alfred C. Hobbs, Day & Newell's salesman came to the Exhibition to sell these locks internationally.

Hotel key made by Yale & Towne Mfg Co of New York for the Astoria; as stamped on the reverse side of the bow. This hotel was built by J.J. Astor, IV in 1897 next to the Waldorf, and later became the highly acclaimed Waldorf-Astoria. All demolished in 1929 to make way for the Empire State Building. This key is in the style of the late Victorian period with Yale having produced the key with a pipe barrel, seemingly to fit a 3-lever lock. No. 478 on the bow seems to be the Room No, but "2334" on the bit? Perhaps Yale's pattern number? The ball and chain appears to be a strong reminder to return the key!

Cotterill's 'Acme' lock invented by Peter Wilson of Birmingham (Patent No. 3257 of 11.11.1869) was further developed about 1880 (no evident Patent) to provide this double-bitted butterfly key. Apart from this, the mechanism was much the same as the original Acme patent lock. Maybe the change was made to provide a cheaper method of production, and having a smaller keyhole it would be better protected against the insertion of gunpowder. The "A - A" number is c.1880.

Davis, George of Windsor (locksmith to Kings - George III and IV; 1798 to 1827).

He obtained patent No. 2306, of 11th April 1799 for a "double chambered lock with cylinders, to which pins are attached in different directions, instead of wards". The internal lock mechanism is shown below. The five pins onto which the key bit fits are visible.

When the key is depressed the sprung hinged pieces - seen here, on both side of the pins are moved down and lift a ball bearing at the rear. These balls fit into recesses in the case beneath, and when lifted this round plate is able to revolve, taking with it the brass 'bolt' shown above the balls, which acts to move the latch.

The lock is large and heavy (7.7" - 19.5cm x 4.8" - 12.2cm) and incorporates Davis patent double chamber. It operates as a latch lock, which might have operated with some safe or vault boltwork; perhaps for banking use.

Linus Yale, Jnr. Treasury lock, key (Patent No. 28710, 12th June 1860 & 32331, 14th May 1861). The most important security feature of this lock is its unique key described here. The bit is detachable and in the open position it would be hidden inside the rectangular shaped section at the base of the key shaft. When the key is inserted in the lock and turned - as illustrated in the left side picture, the bit moves out to expose its steps.

As the shaft is turned further the bit detaches and, inside the lock it is carried away from the keyhole to engage with the levers and operate the mechanism. This separation of the levers from proximity to the keyhole pretty well made them inaccessible to picking through the keyhole.

c.18th century probably French key, with trefoil shaped shaft, intricately cut bit, and a 'stirrup' instrument through its bow. Best guess on what the 'stirrup' does is that it may be fixed to a metal rod within the key shaft. The complex nature of the key and lock drill pin with the trefoil shape inserted suggests that this will be a tight fit; so if the stirrup with its rod is pushed in at times when the key doesn't easily retract, that should help to ease it out.

Early pin tumbler lock key by William Pye of New York. American, Abraham Stansbury moved to England and obtained a patent (No. 2851) on 18th May 1805. Perhaps due to its unusual pin tumbler operation the lock was never really accepted in Britain. So he returned to America where he obtained a U.S. patent on 11.2.1807. That was the first patent to be granted for locks in America.

William Pye was the earliest known maker of padlocks using Stansbury's invention, around 1815. The lock has a rear fixed plate in which are sprung pins (as many as there are points on the key bit - eight in the photo on the left), which project into a circular plate which moves above the fixed plate.

When the key is pushed in, the points on its bit depress the pin tumblers in the top moveable plate until each one reaches the top surface of the fixed plate, to create a line of division (or sheer line). This allows the moveable plate to rotate and lock or unlock the bolt.

James Kyle Bank Lock key (U.S. Patent 5708, 15th August 1848) - the lock is so rare that none are known to exist! However two keys including this one are still here:

This changeable bit safe key measures 6"; 16.5cm and has 21 numerically numbered and adjustable bits. The bit section is shown in the right hand photograph above. A very rare key!

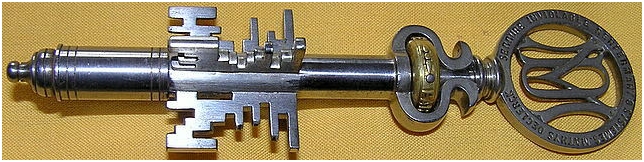

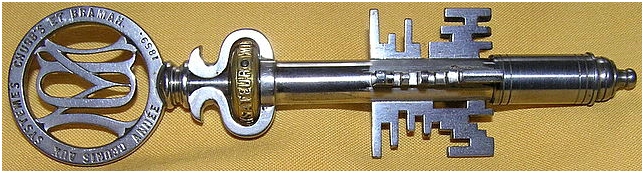

Mathys DeClerck's key (French). Its lock was the only one ever made by DeClerck specifically for an 1859 Exhibition in Paris. Regrettably it was lost in Paris during the war of 1939/45 - but this beautiful key survives! On one side wording on the bow reads "... Aux Systems Chubb's et Bramah, Anne'e 1859."

On the other side is included "Serrure Inviolable" with the maker's name. The bow also has centre entwined DeClerck's intials "M.D.". Wording will also be seen on the moveable brass ring.